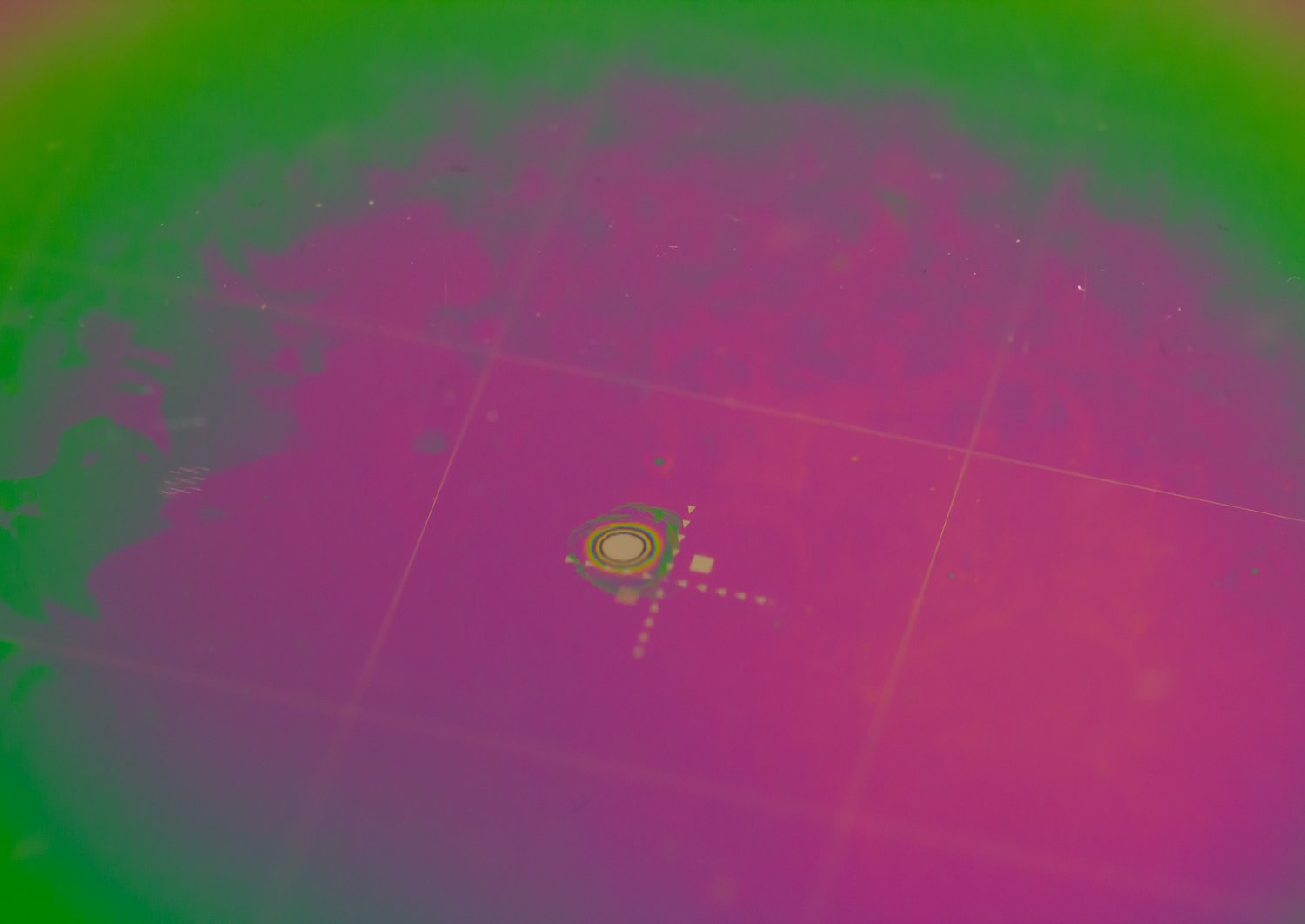

Traditionally, quantum applications involving photons have relied on the use of bulk crystals and waveguides. However, these conventional methods pose limitations, particularly in creating small and versatile systems. To overcome these challenges, researchers at SAL explore a new approach using metasurfaces, special surfaces made up of tiny optical resonators that can control light in innovative ways. By manipulating these surfaces, the researchers can create conditions that allow the generation of multiple entangled photon pairs in a very small space.

Ultrathin metasurfaces for quantum advancements

The utilization of ultrathin metasurfaces as efficient sources of entangled photons holds immense potential for the miniaturization of various quantum devices. These devices play a critical role in space-related applications like protected communications between satellites and quantum sensing.

"We will develop an innovative platform for scalable optical quantum devices. The pursuit of miniaturizing quantum-light sources to micro- and nanoscale dimensions is a critical and ongoing endeavor, driven by the need for denser integration of functional quantum devices in line with modern market trends", says Roman Noskov, Project Leader and Staff Scientist in the field of Integrated Photonics Technologies at SAL.

“We believe that metasurfaces can pave the way for a new era of quantum advancements with real-world implications. The ability to generate entangled photon pairs in such a compact space opens up many possibilities for creating more efficient and practical quantum devices, particularly in the demanding environment of space”, says Mohssen Moridi, Head of Microsystems at SAL.

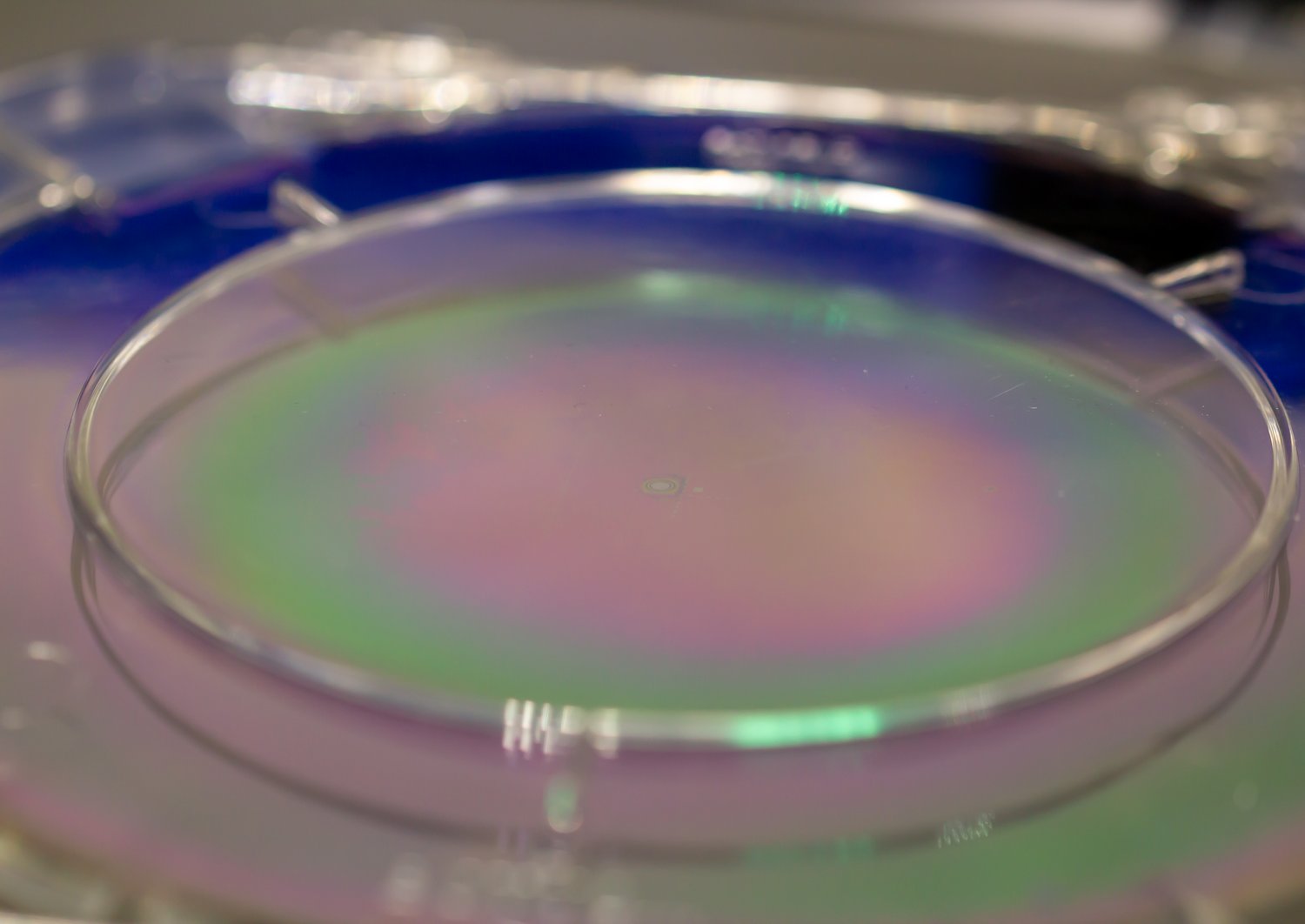

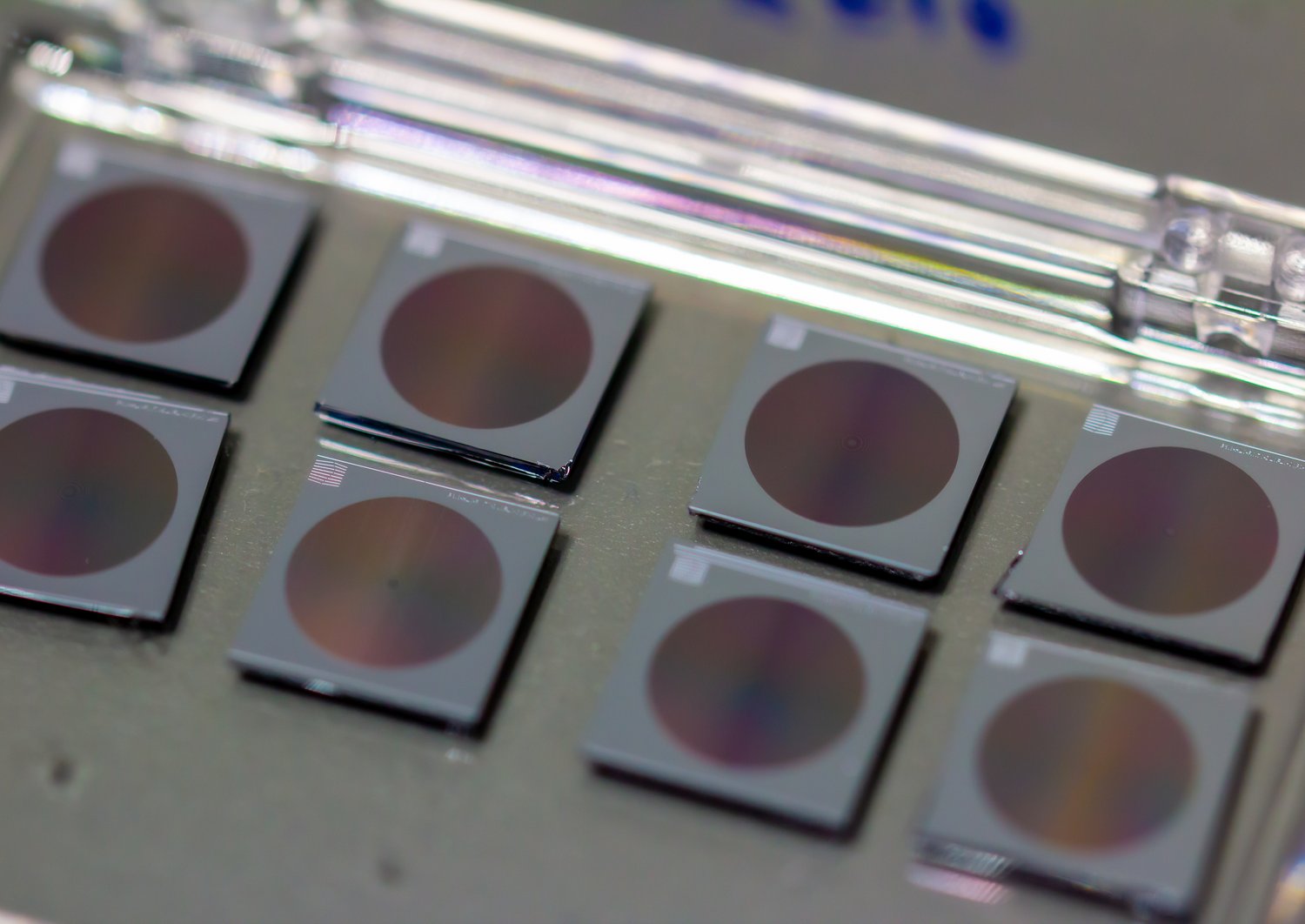

Fabrication of metasurfaces in the SAL MicroFab

The fabrication of these ultrathin metasurfaces will take place in the SAL MicroFab, Austria’s biggest research cleanroom located at SAL in Villach. Designed to accommodate 200 mm wafers, the facility is capable of processing up to 25 wafers in a single batch. The primary objectives of the SAL MicroFab include facilitating fast prototyping, small series production, and the seamless transfer of processes to an industrial scale.