The increasing demand of integrating optoelectronic and micro-optical components in a system-in-package for numerous applications in computing, sensing, biomedicine, micro-electromechanical systems, and communication, requires miniaturized micro-optical components with high degree of dimensional accuracy and surface quality. Compared to conventional lithography techniques confined to 2D to 2.5D structures on planar surfaces, SAL employs state-of-the-art two-photon lithography, which enables 3D printing of micro-optical components with high geometrical precision and surface quality with sub-micron resolution.

Two-Photon lithography is an additive manufacturing system based on the principle of photopolymerization, usually at NIR spectrum region and with ultrashort laser pulses, where two photons are absorbed by the liquid photosensitive material (photoresin) containing liquid polymer, photoinitiator, and monomer. Most of the commercially available photoresin have negligible absorption in near-infrared (NIR) range. Hence, the focal point can penetrate deeply into the resist, resulting in photopolymerization only in the focal volume (voxel) due to several nonlinear effects. By tuning the voxel parameters, great geometrical precision and surface quality of 3D structures can be achieved.

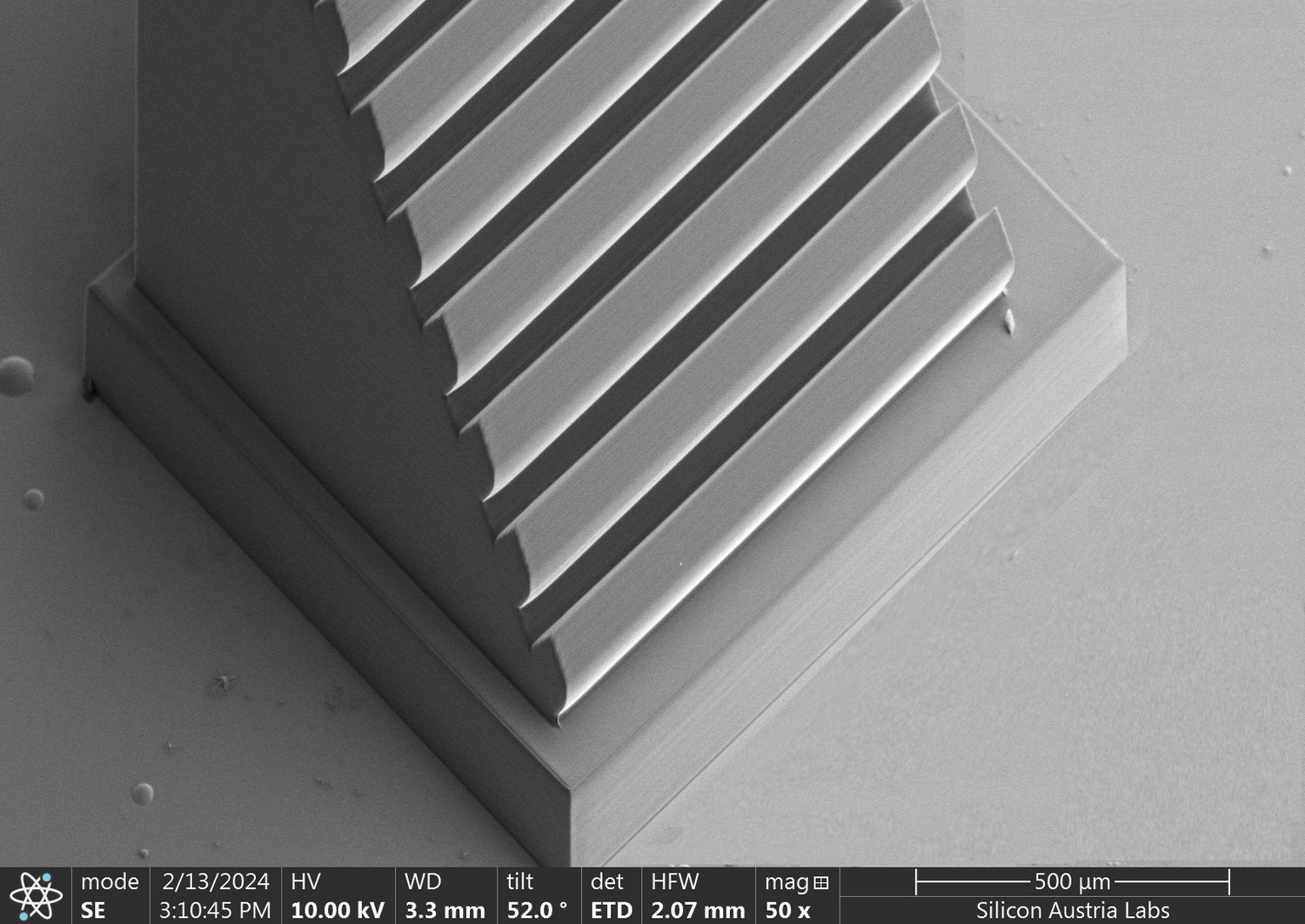

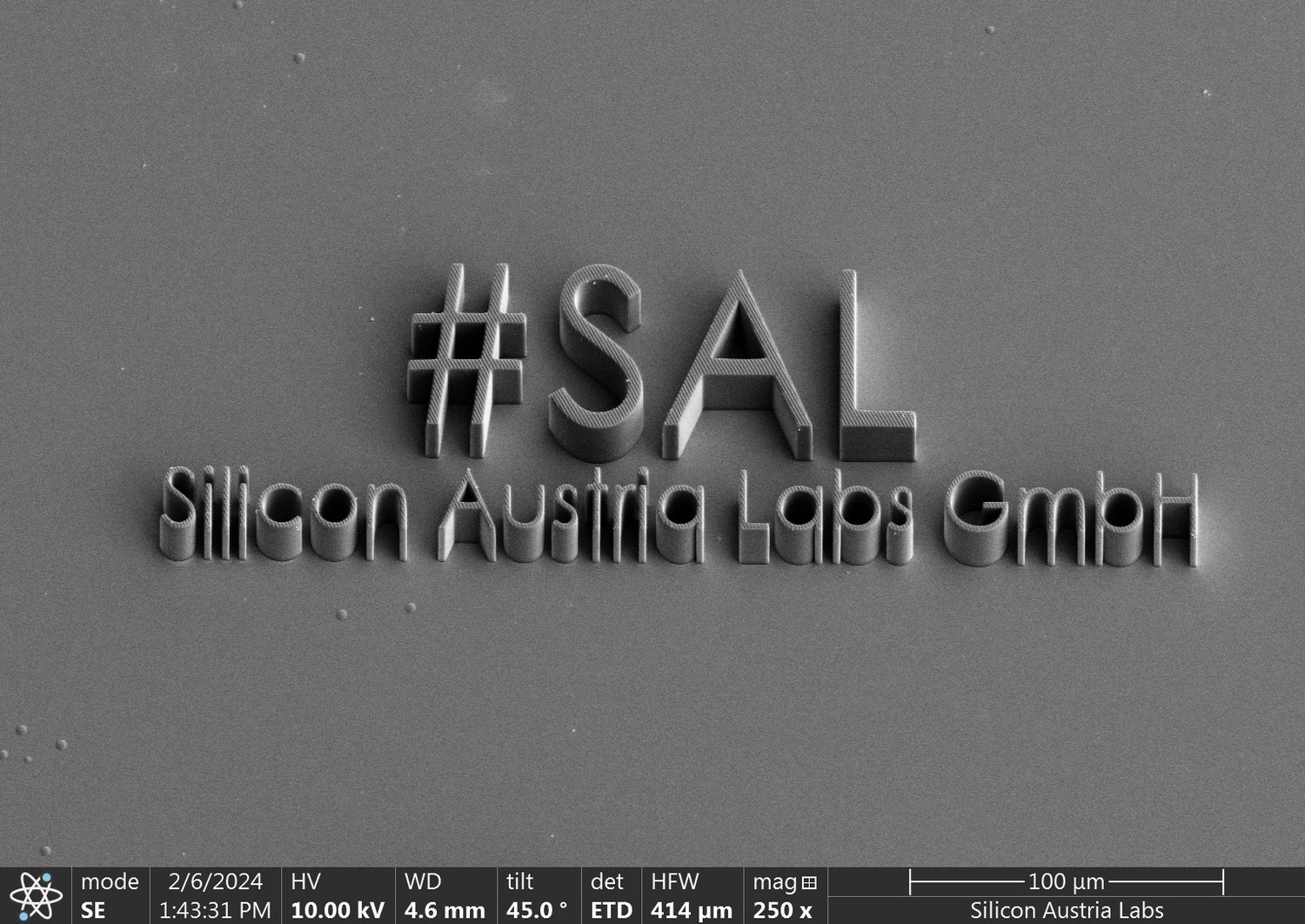

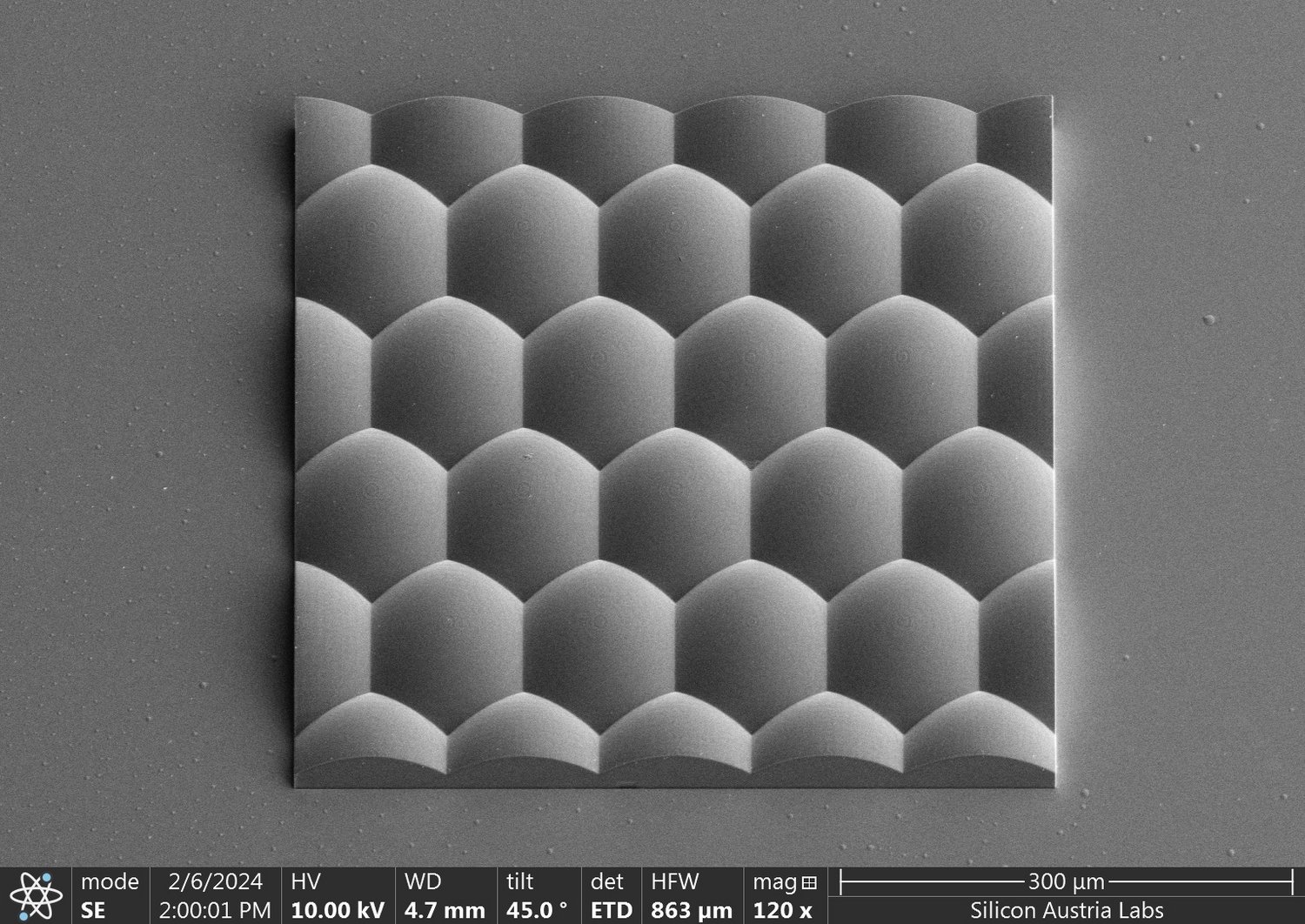

In recent years, SAL has experienced significant growth in the domains of photonic assembly and integration. This progress is attributed to the development of capabilities for fabricating miniaturized optical components, including micro-lenses, beam-splitting components, waveguides, and more. This fabrication extends beyond traditional wafer-based methods, encompassing in-package printing of optical elements to customize light as needed. An integral aspect of this process involves careful consideration of alignment relative to other components or structures. For this, a two-photon polymerization-based 3D printing system (Quantum X align) a state-of-the-art system for printing optical components with submicron resolution, has been procured from Nanoscribe GmbH. The system is equipped with nano precision alignment accuracy using its A2PL (aligned 2-photon lithography) process for printing on optical fiber tips, on photonic integrated circuits as well as the edges of photonic chips. In the images, a microlens array for shaping the light beam, an angled grating on a prism facet, and a logo of SAL are printed.

The acquisition of the 3D printing system, photonic integration, and assembly of miniaturized optical components, as well as combining it with other packaging technologies provides new dimensions of integration on chip level as well as wafer level at SAL.