With additive manufacturing (AM), functional structures (e.g. sensors, electrodes, fine-pitch interconnects, metamaterials etc.) can be realized in a more sustainable and environmentally friendly way and potentially at much lower cost per area, compared to established subtractive photolithography processes. Moreover, the capability of AM to simultaneously deposit multiple materials to form complex 3D structures opens completely new design opportunities.

A current leading technology for additively manufactured electronics is inkjet printing, which is relatively cost-effective, but does not offer the required resolutions for many applications in the field. EHD inkjet printing is an emerging additive technology, that offers printing resolutions smaller than 1 µm. It is not widely used yet in the industry, due to the strong throughput limitations of the single-nozzle systems currently available on the market.

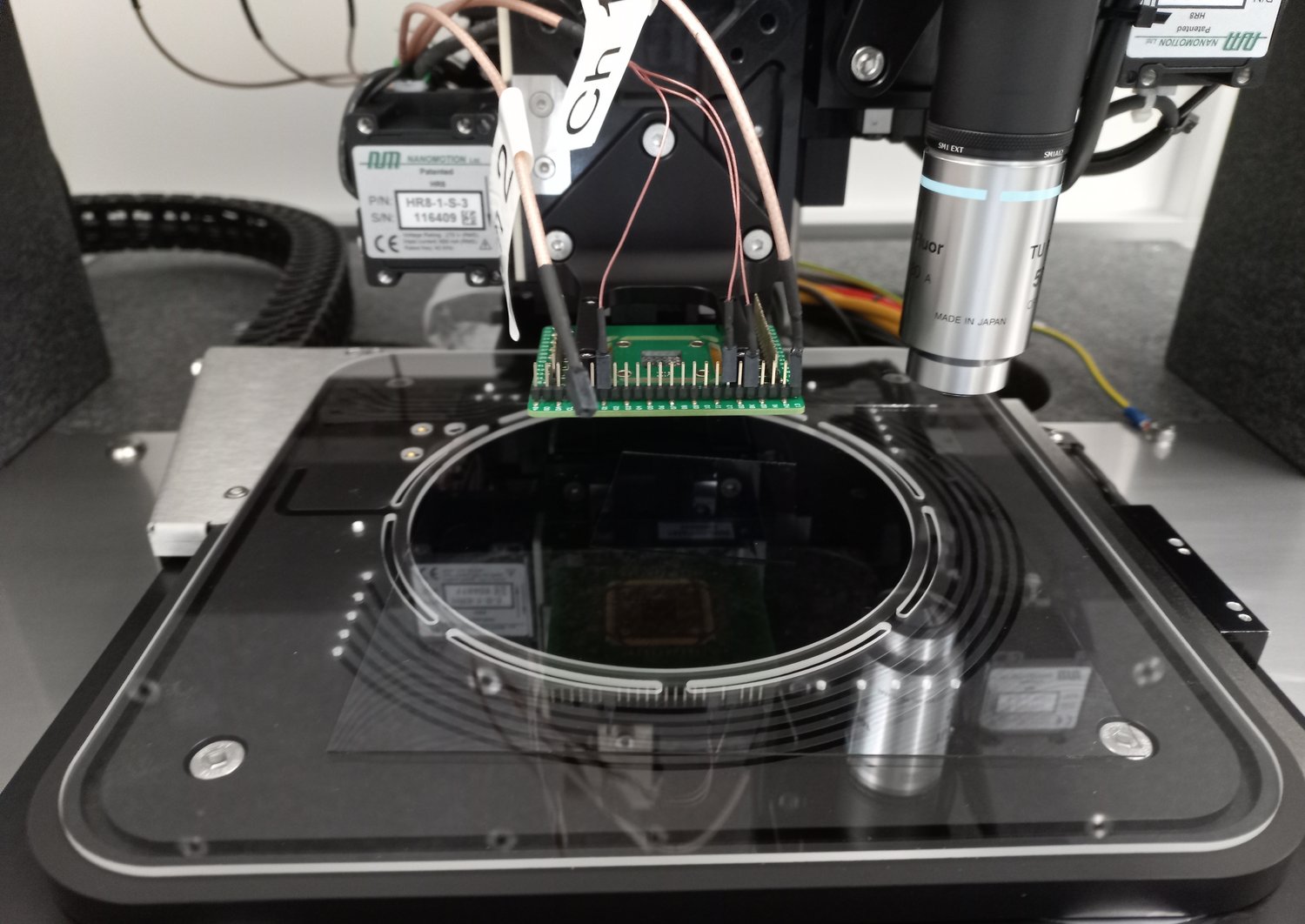

The innovation behind the joint development efforts of SAL and Scrona is a multi-nozzle EHD printing system with the flexibility required in an R&D environment. With Scrona’s prototype MEMS printheads at its core, the system offers printing resolutions down to < 1µm, self-aligned multi-material printing, in-situ process inspection for efficient ink testing, precise 3D positioning and alignment capabilities, in-situ thermal annealing and more. The multi-nozzle MEMS printheads not only offer higher throughput, but printing is more robust (reduced clogging, large standoff-height) and the optimized nozzles offer a much wider ink compatibility e.g. in terms of viscosity range.

SAL offers contract and cooperative R&D to industrial partners, who want to develop technologies along the value chain of electronic based systems, from wafers to intelligent systems. The field of application is quite wide: “We can use the EHD printer for selective repair and modification, rapid prototyping or printing of advanced material. From temperature sensors to metamaterial design and biomedical applications – the sky is the limit”, says Goran Mišković, Senior Scientist in the research unit Heterogeneous Integration Technologies at SAL.

Technical details of the EHD printer:

- Droplet volume in attoliter range

- Printing resolution of <1-10 µm (depending on ink and substrate properties)

- 150x150 mm printing area

- Multi-nozzle and multi-material printheads

- Minimal fluid volume of <1µL for printhead priming

- Compatible with a variety of substrates (Si wafers, polymers, ceramics, glasses, etc.)

- Compatible with many solvents (polar, apolar)

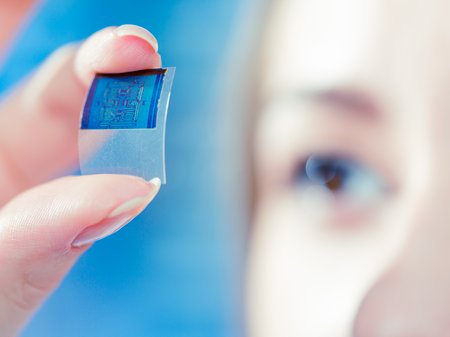

![[Translate to English (US):] A close up of a printed sensor](/fileadmin/_processed_/d/b/csm_SAL_Villach_2021_Helge_Bauer__137__3305b0f6fd.jpg)